Mosfet Gate Driver Circuit Using Optocoupler

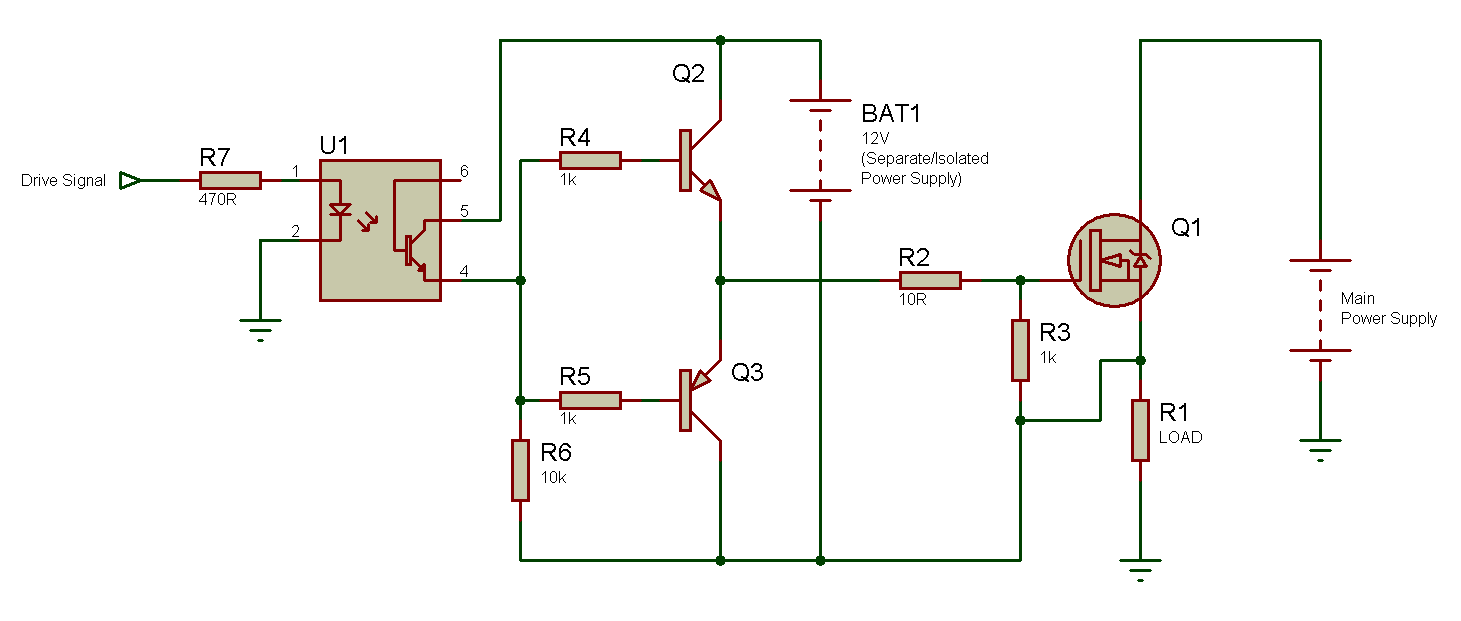

VOL 46Implementing an Isolated Half-Bridge Gate DriverMany applications, ranging from isolated dc-to-dc power supply modules that call for high power density and efficiency, to solar inverters, where high isolation voltage and long-term reliability are critical, use isolated half-bridge gate drivers to control large amounts of power. This article will discuss details of these design concepts to illustrate the ability of isolated half-bridge gate driver ICs to provide high performance in a small package.A basic half-bridge driver with optocoupler isolation, shown in Figure 1, controls output power by driving the gates of high- and low-side N-channel MOSFETs (or IGBTs) with signals of opposite polarity. The drivers must have low output impedance, to reduce conduction losses, and fast switching—to reduce switching losses. For accuracy and efficiency, the high- and low-side drivers need very closely matched timing characteristics in order to reduce the dead time when one switch of the half bridge turns off before the second switch turns on. High-voltage half-bridge gate driver.As shown, a conventional approach to implementing this function uses an optocoupler for isolation, followed by a high-voltage gate-driver IC. A potential drawback of this circuit is that the single isolated input channel relies on the high-voltage driver circuit for the needed channel-to-channel timing match, as well as the required dead time.

Another concern is that high-voltage gate drivers do not have galvanic isolation; instead, they rely on the IC’s junction isolation to separate the high-side drive voltage from the low-side drive voltage. Parasitic inductance in the circuit can cause the output voltage, V S, to go below ground during a low-side switching event. When this happens, the high-side driver can latch up and become permanently damaged.

Optocoupler Gate DriverAnother approach, shown in Figure 2, avoids the problems of high-side to low-side interactions by using two optocouplers and two gate drivers to establish galvanic isolation between the outputs. The gate-driver circuit is often included in the same package as the optocoupler, so two separate optocoupler-gate-driver ICs are commonly required to complete the isolated half bridge—increasing the physical solution size. Note also that the optocouplers are manufactured separately, even if two are packaged together, limiting the ability to match the two channels. Allowing for this mismatch will increase the required dead time between switching one channel off and turning the other channel on, reducing efficiency.

Dual optocoupler half-bridge gate driver.The optocoupler’s response speed is limited by the capacitance of the primary side light-emitting diode (LED); while driving the output to speeds up to 1 MHz, it will also be limited by its propagation delay (500 ns max) and slow rise and fall times (100 ns max). To run an optocoupler near its maximum speed, the LED current must be increased to more than 10 mA, consuming more power and reducing the optocoupler’s lifetime and reliability—especially in the high-temperature environments common in solar inverter and power supply applications. Pulse Transformer Gate DriverNext, consider circuits where the galvanic isolation is provided by transformer coupling. Their lower propagation delays and more accurate timing can provide a speed advantage over optocouplers. In Figure 3, a pulse transformer is used; it can operate at the speeds often needed for half-bridge gate-driver applications (up to 1 MHz). A gate-driver IC can be used to deliver the high currents needed for charging the capacitive MOSFET gates. Here, the gate driver differentially drives the primary of the pulse transformer; the two secondary windings drive each gate of a half bridge.

In this application, pulse transformers have the advantage of not requiring isolated power supplies to drive the secondary side MOSFETs. Pulse transformer half-bridge gate driver.However, a problem can occur when large transient gate-drive currents flowing in the inductive coils cause ringing. This can switch the gate on and off when not intended, damaging the MOSFETs. Another limitation of pulse transformers is that they may not work well in applications that require signals with more than 50% duty cycle, as they can deliver only ac signals, and the core flux must be reset each half cycle to maintain a volt-second balance. A final difficulty: the magnetic core and isolated windings of the pulse transformer require a relatively large package which, combined with the driver IC and other discrete components, creates a solution that may be too large for many high-density applications.

Digital Isolator Gate DriverConsider now applying a digital isolator in an isolated half-bridge gate driver. The digital isolator in Figure 4 uses a standard CMOS integrated-circuit process with metal layers to form transformer coils separated by polyimide insulation. This combination achieves more than 5 kV rms (1-minute rating) isolation, which can be used in robust isolated power supply and inverter applications. Digital isolator with transformer isolation.As shown in Figure 5, the digital isolator eliminates the LED used in an optocoupler—and its associated aging problems—consumes far less power, and is more reliable. Galvanic isolation (dashed lines) is provided between input and output, and between the two outputs, eliminating high-side to low-side interactions. The output drivers feature a low output impedance to reduce the conduction losses—and a fast switching time to reduce the switching losses. Digitally isolated 4-A gate driver.Unlike an optocoupler design, the high- and low-side digital isolators are manufactured on a single integrated circuit, with inherently matched outputs for better efficiency.

Note that the high-voltage gate driver integrated circuit shown in Figure 1 has additional propagation delay in the level-shifting circuit, so it cannot match channel-to-channel timing characteristics as well as the digital isolator. Furthermore, integration of the gate drivers with isolation in a single IC package reduces the footprint of the solution to a minimum. Common-Mode Transient ImmunityIn many half-bridge gate-driver applications for high-voltage power supplies, very fast transients can occur across the switching elements. In these applications, a rapidly changing voltage transient (high dV/dt) that capacitively couples across an isolation barrier can cause logic transition errors across the barrier. In an isolated half-bridge driver application, this could turn on both switches in a cross-conduction episode that could destroy the switches. Any parasitic capacitance across the isolation barrier tends to be a coupling path for common-mode transients.Optocouplers need to have very sensitive receivers to detect the small amount of light transmitted across their isolation barrier, and their outputs can be upset by large common-mode transients.

The optocoupler sensitivity to common-mode transient voltages can be reduced by the addition of a shield between the LED and the receiver; a technique used in most optocoupler gate drivers. The shield can improve the common-mode transient immunity (CMTI) from a standard optocoupler rating of less than 10 kV/μs to as much as 25 kV/μs for an optocoupler gate driver. This rating may be suitable for many gate-driver applications, but CMTI of 50 kV/μs or more may be needed for power supplies with large transient voltages, and for solar inverter applications.Digital isolators can deliver higher signal levels to their receivers and withstand very high levels of common-mode transients without data errors. Transformer-based isolators, as four-terminal differential devices, can provide low differential impedance to the signal and high common-mode impedance to the noise—which can result in excellent CMTI. On the other hand, digital isolators that use capacitive coupling to create a changing electric field and transmit data across the isolation barrier are two-terminal devices, so the noise and the signal share the same transmission path.

With a two-terminal device, the signal frequencies need to be well above the expected frequency of the noise so that the barrier capacitance presents low impedance to the signal and high impedance to the noise. When the common-mode noise level becomes large enough to overwhelm the signal, it can upset the data at the isolator output. An example of a capacitor-based isolator data upset is shown in Figure 6, where the output (Channel 4, green line) has glitched low for 6 ns during a common-mode transient of only 10 kV/μs. Capacitor-based digital isolator with CMTI of.

Brian KennedyBrian Kennedy is an applications engineer with the Digital Isolator Group at Analog Devices, Inc. He has been with ADI since April 2008 and is responsible for Gate Driver and Power Supply Digital Isolation Products.

Nick evans carbondale. About the AuthorNick Evans, BSc, MD, FRCS (Orth), is an orthopedic surgeon specializing in sport injury. He studied medicine at the University of London, England, and trained in orthopedic surgery at the University Hospital of Wales. Evans gained additional skills in arthroscopic surgery at the Southern California Center for Sports Medicine and the University of California at Los Angeles.Evans is a highly regarded authority on strength training, nutrition, and weight training injuries.

He has a Bachelor of Science in Electrical Engineering (BSEE) from State University of New York (Buffalo.)Related Products.3 kV rms Isolated Precision Half-Bridge Driver, 4 A Output.5 KV rms Isolated Precision Half-Bridge Driver, 4 A OutputRelated Categories.Related Markets & Technology. The cookies we use can be categorized as follows: Strictly Necessary Cookies: These are cookies that are required for the operation of analog.com or specific functionality offered. They either serve the sole purpose of carrying out network transmissions or are strictly necessary to provide an online service explicitly requested by you.

Analytics/Performance Cookies: These cookies allow us to carry out web analytics or other forms of audience measuring such as recognizing and counting the number of visitors and seeing how visitors move around our website. This helps us to improve the way the website works, for example, by ensuring that users are easily finding what they are looking for. Functionality Cookies: These cookies are used to recognize you when you return to our website. This enables us to personalize our content for you, greet you by name and remember your preferences (for example, your choice of language or region). Loss of the information in these cookies may make our services less functional, but would not prevent the website from working.

Targeting/Profiling Cookies: These cookies record your visit to our website and/or your use of the services, the pages you have visited and the links you have followed. We will use this information to make the website and the advertising displayed on it more relevant to your interests.

We may also share this information with third parties for this purpose.

Two new sets of high speed gate drive optocoupler devices from Avago, the and, and the and are 1 A and 2.5 A gate drive optocouplers designed to protect and drive Power MOSFET and SiC MOSFET for high switching frequency applications such as inverter, motor control and switching power supply. In terms of propagation delay, the optocouplers are twice as fast (120 ns maximum) as the company’s previous generation. The devices contain an AlGaAs LED, which is optically coupled to an integrated circuit with a power output stage.

The high operating voltage range of the output stage provides the drive voltages required by gate controlled devices. The voltage and high peak output current ideally suit the optocouplers for direct driving MOSFETs at high frequency for high efficiency conversion.

Samples of the ACPL-P/W345, ACPL-P/W346 gate drive optocouplers, and evaluation boards, are available now. FETs are mono-polar transistors.

The current passing from drain to source doesn’t cross a P-N junction, as in a bipolar transistor. Because of this, the parts are resistive when you turn them on with a gate signal. The on-resistance of a FET is a fundamental spec of the transistor. The lower it is, the less heat is generated in the part by the current passing through it.

The on-resistance depends on the impurity doping in the silicon die, the metal lead-frame size, and size of the bond wires the manufacturer uses to connect the die to the pins.A physically large die will have lower on-resistance, all other things being equal. The breakdown rating of the transistor is directly proportional to the on-resistance. A few milliohms of resistance is much more common for low-voltage parts than for parts with a breakdown voltage of 150 V. A 1000-V part will have an on-resistance of 10 Ω.Due to the slower mobility of holes versus electrons, P-channel FETs will have higher on-resistance than N-channel types.

Gate-drive voltage is another factor to consider. Driving the gate terminal with a 10-V signal will give a lower on-resistance than a 5-V drive signal. If you’re operating the transistor from logic, you must read the datasheet carefully to learn the on-resistance at that drive voltage.One benefit of the resistive nature of MOSFETs is that you can parallel them to reduce the total on-resistance. Bipolar transistors will; that is, tend to take a little more current, which makes one heat up more and, thus, making it take even more current. While paralleling FETs is fairly straightforward, you have to ensure that the gate traces on the PCB are of equal length and impedance so that the multiple transistors turn on and off at exactly the same. Placing a small series resistor on each gate circuit board trace may help damp oscillations at the expense of slower switching.To get a sampling of five FETs with low on-resistance, we have focused on one package, the.

Gate Driver Circuit For Mosfet

This is a good medium-sized transistor that can take 100 A of current, while still small enough to be used in compact designs. The DPAK also has much better power ratings than TO-92, or SOT-23 packages, while being half the size of the T0-220 package. Here are five FETs in the DPAK package with low on-resistance, sometimes called R DS(on) (resistance from drain to source, on):1. The from Infineon has an R DS(on) of 2 mΩ with a breakdown voltage of 40 V. This is with a 10-V gate-drive signal.2. The from Toshiba has an R DS(on) of 6.5 mΩ with a breakdown voltage of 100 V.

This is with a 10-V gate-drive signal.3. The from ON Semiconductor has an R DS(on) of 22 mΩ with a breakdown voltage of 150 V.

This is with a 10-V gate-drive signal.4. The from Alpha and Omega Semiconductor has an R DS(on) of 5.7 mΩ with a breakdown voltage of 20 V. This is with a 2.5-V gate-drive signal.5 The P-channel from Vishay Siliconix has an R DS(on) of 7 mΩ with a breakdown voltage of 30 V. This is with a 10-V gate-drive signal.If you need to control a large current with low power loss in your next circuit design, be sure to check out these parts.